AI in Business has been accelerating over the past few years. Take, for example, the use of generative AI (GenAI) in OpenAI’s ChatGPT, which showcases to the world the colossal tasks that can be achieved with simple prompts.

AI’s rise shows no signs of slowing, with advances in AI in Manufacturing spearheading innovation across a field long steeped in manual checks and processes.

From predicting machine failures that are yet to occur to reimaging product innovation, these AI examples demonstrate that, like other global industries, a digital transformation in manufacturing is in full motion.

In this article, we’ll highlight fourteen examples of AI in manufacturing that showcase the diverse ways the technology is being applied in the sector.

AI in manufacturing examples at a glance:

| AI Technology | Function | Category |

| Predictive maintenance | Tracks vibration, heat, and pressure to spot early signs of machine failure. | Smarter production and factory operations |

| Robotic process optimization | Adjusts robot paths and timing using past task data to shorten cycle times. | Smarter production and factory operations |

| AI-collaborative robots (“cobots”) | Reacts to human gestures, slowing or pausing when people enter shared zones. | Smarter production and factory operations |

| Asset Performance Management (APM) | Monitors output, wear, and runtime to flag underperforming equipment. | Smarter production and factory operations |

| Quality assurance (QA) | Uses high-speed cameras and pattern detection to catch surface defects. | Smarter production and factory operations |

| Industrial Internet of Things (IIoT) | Connects sensors across machines to record flow rates, energy use, and output. | Smarter production and factory operations |

| AI-enhanced Extended Reality (XR) | Projects provide step-by-step repair guides in real-time through AR headsets. | Smarter production and factory operations |

| Live decision-making | AI flags delays or material shortages during shifts using current sensor data. | Smarter production and factory operations |

| Generative AI (GenAI) | Auto-drafts SOPs, maintenance notes, and part descriptions from input prompts | Workforce and process efficiency |

| Intelligent Document Processing (IDP) | Scans and sorts manuals, inspection forms, or invoices into structured formats. | Workforce and process efficiency |

| Predictive demand forecasting | Uses past order data and seasonal trends to estimate next production runs. | Supply chain and product planning |

| Supply chain management | Recalculates delivery routes or supplier timelines when delays appear. | Supply chain and product planning |

| Smart fulfillment systems | Picks pack sizes, loading orders, and shipment schedules based on item size and speed. | Supply chain and product planning |

| Product innovation | Simulates material changes or new part shapes to test design impact. | Supply chain and product planning |

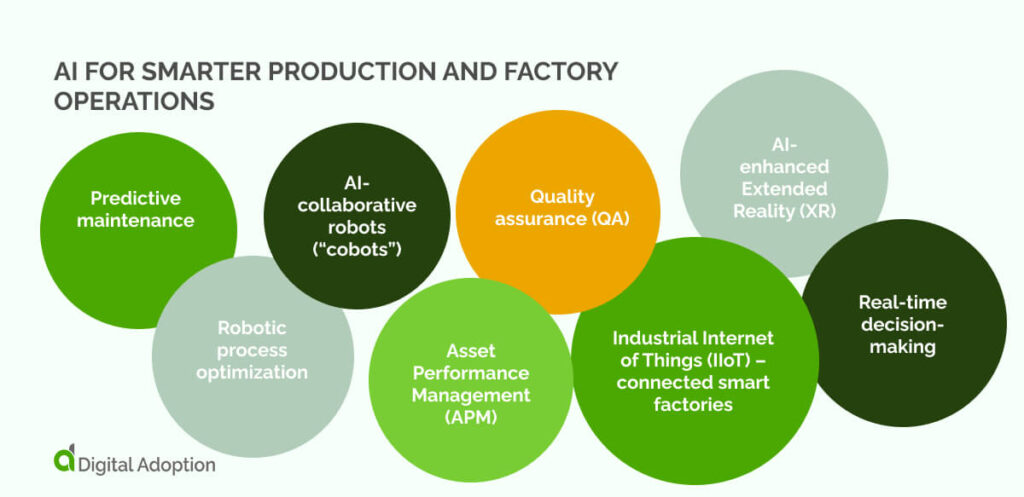

AI for smarter production and factory operations

This manufacturing sub-category explores AI technologies that enhance on-the-ground operations, monitor asset health, and deploy automation across factory settings.

Predictive maintenance

One of AI’s largest benefits is its ability to glean vast amounts of data on factory equipment and identify irregularities within that information. This makes it a decisive tool for predictive maintenance.

It may assess that breakdowns occur more often in certain machinery or detect if a part wasn’t replaced in time. As a result, it can preempt equipment downtime before it happens.

AI can monitor the entire asset portfolio, integrating systems to share information and shift resources between nodes. This prevents operation silos and reduces redundant actions.

It does this through equipment sensors connected to the Internet of Things (IoT), capturing real-time data and flagging it when readings fall outside normal parameters.

Robotic process optimization

Robotic process optimization guided by AI can enhance the operational excellence and quality assurance of manufacturing firms.

AI robotic process optimization instructs factory robots to carry out automated and routine actions. Machine learning algorithms (ML) work behind the scenes, assessing data from equipment sensors, digital workflows, and operational demands to adjust and balance operations in real time.

If process demands shift, AI can autonomously alter workflows and reassign robots to support more pressing tasks. It can also use data for predictive maintenance, detect system analysis discrepancies, and build statistical models for failure.

AI-collaborative robots (“cobots”)

Cobots, or AI-driven solutions such as collaborative robots or droids, are intuitive machines that augment operational functions and assist human workers. Cobots take over labor-intensive activities in manufacturing environments where assembly lines and material handling require muscle power beyond human capabilities.

The hazards existing in manufacturing settings mean that cobots need to perform with precision, be coded with heightened sensitivity and pressure detection, and be able to maneuver safely alongside humans.

Cobots aren’t restricted to physical limitations in factory settings and can be deployed and directed to complete different tasks. Configurable programming also makes them flexible for performing future activities.

Asset Performance Management (APM)

A healthy asset portfolio is a marker of sustainable operations and digital transformation. AI now oversees asset performance management (APM) and computerized maintenance management systems (CMMS), delivering constant oversight into equipment health in manufacturing.

AI automatically tracks KPIs through machine sensors, giving it a live status of critical equipment components. Gathering this analytical data can predict when assets might break down, focus on underperforming equipment, or detect the need for early maintenance after a missed inspection.

APM powered by AI extends asset lifecycles and protects expensive resources, helping operations avoid turning into losses.

Quality assurance (QA)

Quality assurance (QA) ensures consistent standards are baked into every manufacturing process. Consumers’ expectations and supply chain demands require high-calibre products and services.

AI is making QA airtight, supporting tasks traditionally handled by humans. It uses computer vision and anomaly detection to scan production lines, locate defects, and spot misaligned parts in inventory. Big data trains AI to flag irregular patterns or missing stock, driving big data adoption across industries, aiming to boost efficiency and accuracy.

With pinpoint precision, AI spots what humans often miss. It traces defects back to upstream causes, removes flaws, and helps maintain ISO compliance. Fewer product recalls mean less waste in materials, labor, and time.

Industrial Internet of Things (IIoT) – connected smart factories

In the past, monitoring equipment in manufacturing relied on visual checks from human workers. Repairs and maintenance were scheduled without any statistical backing.

Today, the Industrial Internet of Things (IIoT) tracks asset health in real time, collecting data from machine sensors, equipment networks, and cloud systems to offer a full view of factory activity. Devices stream readings like temperature, unusual movements, humidity, and voltage into a central hub.

AI sorts through this to spot early breakdown patterns, inefficiencies, or faults. IIoT connects systems for factory workers to perform diagnostics remotely, synchronize production, and better control energy and resources.

AI-enhanced Extended Reality (XR)

Extended reality (XR) layered with AI brings factory floors into sharper focus. Digital instructions, safety cues, and diagnostics appear directly over machinery and digital tools.

Workers wearing AR headsets don’t flip through manuals. Instead, they see live prompts in their line of sight. AI adjusts these overlays in real time, shifting based on task difficulty, role, or system errors.

XR flags it instantly if a part is misaligned or a step skipped. Instead of repeating mistakes, technicians correct them as they go.

Real-time decision-making

Agile decision-making in manufacturing isn’t left to chance. It now relies on AI systems that process live data the second it’s available. AI tracks signals from machines, sensors, and supply lines as they come in.

It detects pain points, mitigating issues like delays or equipment quality. AI can immediately switch schedules, redirect materials, or alert staff when something changes.

AI also automatically addresses small issues before they evolve. These lightning-fast reactions keep production steady, even when equipment, supply, or demand shift without warning.

AI for workforce and process efficiency

This category examines AI tools that automate routine tasks, generate new content, and enhance decision-making for teams.

Generative AI

Industries are leveraging generative AI (GenAI) for an array of applications. Manufacturing is proving no different, with GenAI training on product libraries, design files, and materials data to generate prototypes or production-ready models in seconds.

Mathematically accurate simulations test how a part will perform under pressure or suggest structural tweaks to improve its stability. On the floor, GenAI produces maintenance scripts, repair instructions, or safety checklists tailored to specific machines.

Engineers are now able to test ideas without increasing risks or costs. The flexibility of GenAI means it can turn disparate data into actionable outputs that support product enablement, design, repairs, and daily factory tasks.

Intelligent Document Processing (IDP)

Factories still rely on a steady paper trail of documents, including shipping labels, supplier invoices, safety checklists, and inspection records. Intelligent document processing (IDP) uses AI to scan, read, and sort these documents without human involvement.

It pulls information from PDFs, scanned files, or handwritten notes, then feeds it into factory systems. If a delivery slip is missing details or a part ID doesn’t match, IDP flags it.

IDP eventually learns where errors tend to arise and corrects them faster each cycle, keeping paperwork from stalling operations.

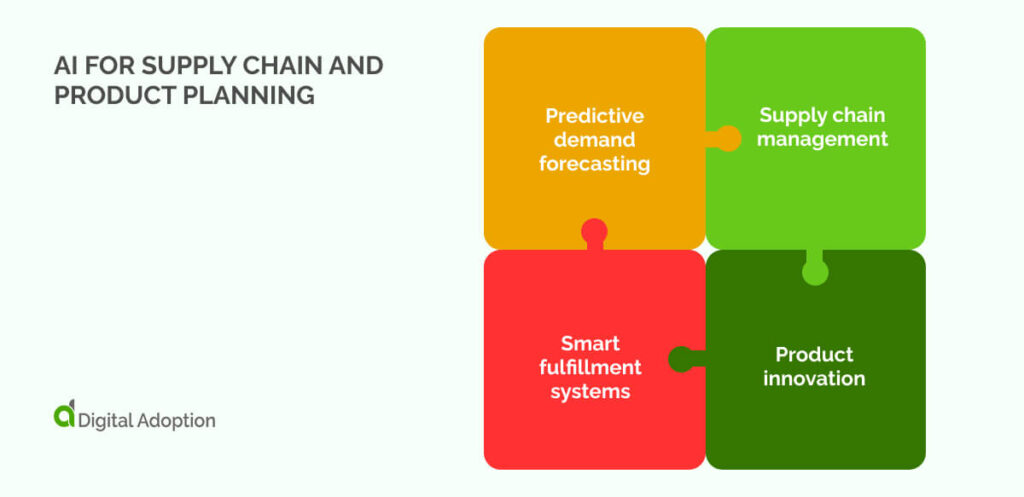

AI for supply chain and product planning

This category focuses on AI applications that improve forecasting, logistics, and product lifecycle development.

Predictive demand forecasting

Manufacturers are using predictive models to map future demand based on seasonal orders, shipping activity, and historical production logs. AI reads patterns buried in spreadsheets, sales records, and sensor outputs to anticipate what will be needed and when.

If order frequency drops or spikes early, forecasting tools update projections. This helps forecast the adoption of new products, avoid overproduction, or running short on parts. Instead of waiting on quarterly reports, factories respond to real-world changes as they happen.

Forecasts are rarely perfect, but early pattern recognition helps planners adjust operations with less guesswork and fewer stock gaps.

Supply chain management

Manufacturing depends on how fast parts and materials arrive. AI watches over supply routes, tracks delays, and checks how reliable suppliers are.

It can spot weak points like late shipments or damaged parts before they cause trouble. When problems arise, the system finds new routes or slows production until supplies catch up.

Over time, AI builds a map of what works and the best way to approach predictable problems. It doesn’t fix everything, but it supports supply chain digital transformation by helping factories stay organized and prepared in the event of delays or shortages.

Smart fulfillment systems

Getting products to customers takes more than just fast shipping. AI tools help track orders, check warehouse stock, and keep packing on schedule.

If something goes missing or breaks down, the system finds a fix, either rerouting tasks or alerting someone to step in. These tools learn over time, spotting patterns that cause mistakes.

They don’t rush everything out the door. Instead, they help each step fit together so orders get out clean, on time, and with less waste.

Product innovation

Designing new products often means reworking old ones. AI helps sort through past designs, test results, and customer feedback, making it a valuable tool in innovation management.

It suggests small changes, like lighter parts or stronger materials, and runs tests without building anything first. This helps engineers determine what might work before they begin building.

The system doesn’t replace human ideas, but handles the small stuff like math, materials checks, and failure tests. With AI, factories test more options quickly and waste less time guessing what to try next.

Ensuring safe and responsible AI in manufacturing

No manufacturing medium is without the benefit of AI.

Much like in other industries, its potential is helping to innovate the sector in new and exciting ways. However, tangible AI safety risks exist today that threaten to derail AI-led transformations at manufacturing firms.

Model and algorithmic integrity must be embedded into any AI design intended for use in manufacturing processes.

It’s up to CIOs and CDOs to thoroughly vet AI solutions, inspecting them under the hood to ensure adherence to ethical parameters and the use of adequate training methods. Bias mitigation and comprehensive training data must underpin the whole solution.

It’s also key to ensure AI complies with the necessary data privacy and security laws that help inform businesses how to use AI ethically. IBM research reveals that the global average cost of a data breach in 2024 has reached $4.88 million, a 10% rise from last year and the highest recorded to date.

People Also Ask

-

What is the future of AI in manufacturing?AI is becoming commonplace in factories to manage equipment, coordinate tasks, and automatically handle shifts in supply or demand. It’s not a blanket solution; AI adapts to context. Model training eventually molds to factory data, understanding better how to handle more specialized work. Human employees will be key for overseeing AI implementation, but the split between manual and automated will keep shifting.

-

Is AI only for large manufacturers?No, smaller manufacturers are finding use cases that fit their scale. Some AI tools are modular or work with older systems. Others are built to run through cloud platforms without needing full rebuilds. It depends less on size and more on where the gaps are.

-

Can AI help reduce manufacturing waste?AI can find defects early in the production process. It learns where materials are used too much, energy is wasted, and equipment wear causes extra costs. Small improvements add up quickly, helping factories work better and save money over time.

![14 Examples of AI in Manufacturing [2025]](https://www.digital-adoption.com/wp-content/uploads/2025/06/14-Examples-of-AI-in-Manufacturing-2025.jpg)