The pharmaceutical industry is fascinating, at times even paradoxical, when it comes to digital transformation.

Despite the years of research and millions of dollars in the clinical trials involved in developing new life-saving drugs, drug manufacturing processes often use decades-old technology like the batch process.

However, this is starting to change with the explosion of interest in generative AI, as pharmaceutical companies use AI in clinical development to conduct research more efficiently.

To help you understand the significance of digital transformation in pharma, we will explore the following topics:

- What is digital transformation in pharma?

- Why is digital transformation in pharma important?

- What are the benefits of digital transformation in pharma?

- What are the disadvantages of digital transformation in pharma?

- 3 top strategies for digital transformation in pharma

- What is digital transformation in pharma?

- Why is digital transformation in pharma important?

- What are the benefits of digital transformation in pharma?

- What are the challenges of digital transformation in pharma?

- 3 top strategies for digital transformation in pharma

- Sanofi: A use case for digital transformation in pharma

- Balance safety with technology for success in pharma

What is digital transformation in pharma?

Digital transformation in pharma is incorporating digital tools into a pharmaceutical organization. Its main goal is to improve services by updating existing processes and making them quicker and more efficient using digital innovation.

Why is digital transformation in pharma important?

Pharmacology constantly changes as new medications are developed, and this pace of change needs to be matched with changing and current technologies. There are three main reasons for this: customer expectations, competition, and the counterfeit market.

Changing customer expectations

In the Industry 4.0 era, customers can easily access substantial health information through online channels. By using devices like fitness trackers and smartwatches, they feel empowered to manage their health.

Pharmaceutical companies are focusing more on enhancing patient engagement than ever before, with digital technology representing how to improve their understanding of their needs as part of a customer experience transformation to foster stronger relationships and build retention.

Higher external competition

Big data is a major driving force in today’s digital world. In addition to facing competition from within the industry, the pharmaceutical sector is also being threatened by external factors.

Large technology companies like Apple and IBM are now entering the healthcare industry with advanced devices and digital health communities. This is allowing them to gain access to enormous amounts of health data.

Therefore, pharmaceutical companies must prioritize digital solutions to stay competitive.

The drug counterfeit market

Counterfeit drugs have become a growing problem worldwide. Still, digital technology can help combat it with Blockchain and Radio Frequency Identification (RFID) tags to track the medicine’s origin and increase transparency in the supply chain.

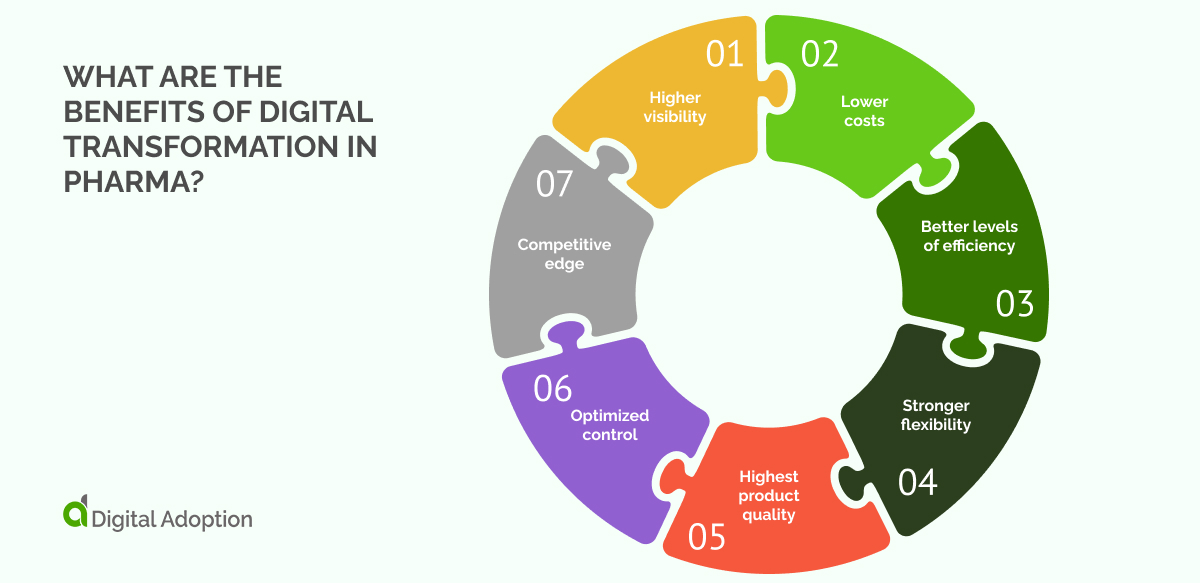

What are the benefits of digital transformation in pharma?

Let’s look at the benefits of digital transformation in pharma to understand the incentives for investing.

Higher visibility

Digital technologies can improve supply chain visibility, enabling companies to make more informed business decisions.

By integrating their supply chains fully through digitalization, organizations can enhance their manufacturing processes with more responsive and adaptable business operations.

You can make faster and more effective decisions by implementing changes that improve accuracy, inventory levels, manufacturing efficiency, and service via actionable insights and advanced analytics.

A pharmaceutical company can gain valuable insights to improve its drug designs by increasing its data visibility across value chains through digitalization.

Lower costs

The pharma industry can reduce per-person expenses by implementing digital transformation. This includes using machine learning, artificial intelligence, and machine-to-machine communication in manufacturing facilities.

Using digital processes in manufacturing operations for pharmaceutical companies leads to improved efficiency, automated corrective actions, and better preventive maintenance.

This helps to reduce errors and malfunctions while minimizing repair expenses, liabilities, and downtime. Digitalization ultimately results in more significant cost savings.

Better levels of efficiency

Pharmaceutical companies can enhance their manufacturing efficiency and productivity by implementing the four main digital transformation.

Digitalization enables businesses to gather data from all their locations, providing valuable insights to decision-makers about the overall operational effectiveness of their companies.

These insights can be examined to identify any process inefficiencies and devise plans for enhancing these areas.

Digitalization can help pharma companies automate manufacturing processes, increasing efficiency and reducing resource usage.

This means they can complete more work in less time without relying as heavily on manual labor. Additionally, digitalization provides insight for analysis and implementation to improve efficiency further.

Stronger flexibility

The pharma industry can enhance medication and vaccine production speed with more flexible manufacturing processes through digital transformation, as opposed to traditional fixed processes.

Manufacturing allows companies to produce new drugs using single-use materials, avoiding cleaning and validating current equipment.

Unlike fixed production processes, this versatility saves manufacturing time and helps companies bring drugs and vaccines to the market faster for their customers.

The pharmaceutical industry can use digitalization to create flexible manufacturing equipment that can be adjusted to meet changing patient demands.

Doing so improves patient safety through robotics and automation technology companies use and helps companies ensure medication compliance and improve production efficiency.

Highest product quality

Pharmaceutical companies use procedural data to maintain their product quality. However, some of these organizations still use paper documentation in their facilities, resulting in gaps in the quality assurance process.

According to studies, pharmaceutical companies require at least 6 months to recruit quality management personnel due to the extensive range of systems and data sources they must employ to perform their duties. The absence of instant access to real-time data compounds this.

Pharmaceutical companies can use digital transformation to gather information from various sources, standardize it, and analyze it for better quality assurance.

By enabling real-time monitoring of a plant’s processes and production, it helps identify quality gaps and improves reporting workflows.

Optimized control

Pharmaceutical manufacturing must pay great attention to every step, such as product development, equipment cleaning, and packaging labeling.

Even a minor mistake in any of these processes can ruin the entire batch of products, leading to significant losses in time, money, and resources for companies.

Defective batches can potentially cause significant harm to customers, leading to legal action and harm to the company’s reputation.

Digitalizing manufacturing processes in the pharmaceutical industry allows organizations to have better control over their production. This is achieved through improved product monitoring, visualization, and remote data accessibility.

Doing so allows organizations to promptly identify and address issues with their packaging processes, avoiding errors that could otherwise affect product batches. Ultimately, this leads to increased profitability and cost savings.

Competitive edge

integrating digital technologies, pharmaceutical companies can enhance manufacturing operations, minimize expenses, and enhance production quality.

Pharmaceutical companies that have not implemented digitalization in their operations are at a disadvantage compared to businesses that have embraced it due to its significant benefits.

Pharmaceutical companies can achieve significant business benefits that differentiate them from other organizations by emphasizing digitalization within their supply chain.

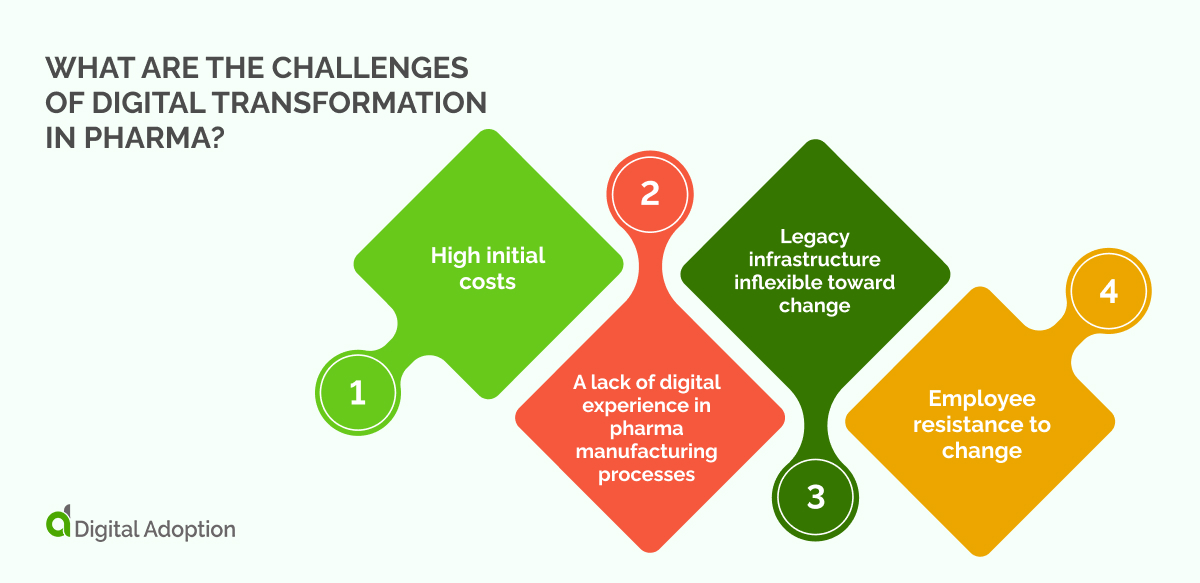

What are the challenges of digital transformation in pharma?

Despite the benefits of digital transformation in pharma, there are challenges to overcome before enjoying these advantages. The first of these challenges and digital transformation risks is the high initial equipment costs.

High initial costs

companies usually have the resources to adopt new digital solutions, while small and medium-sized manufacturers often do not. As a result, SMBs may choose to keep using their old systems, especially if they are not experiencing any obvious problems.

MB manufacturers can benefit from investing in advanced technologies with a sound strategy. These technologies can provide measurable advantages, such as:

- Optimized operational efficiency.

- More detailed and efficient data visibility and analysis.

- Lack of Digital Expertise in Pharmaceutical Manufacturing.

A lack of digital experience in pharma manufacturing processes

It is widely known that manufacturing has become faster, more efficient, and increasingly automated. However, manufacturing is still in the early stages of adopting digital technologies for many pharmaceutical companies compared to other industries.

Manufacturing leaders might not comprehend the latest advancements’ technical aspects, such as:

- Machine learning.

- Artificial intelligence.

- Robotic process automation.

- Advanced data analytics.

- Cloud-centric computing.

- Digital marketing.

A lack of direct knowledge may cause some delay, but this should not deter manufacturers from pursuing digital transformation.

Legacy infrastructure inflexible toward change

Important decisions must be made when choosing advanced manufacturing technologies like pharmaceutical ERP systems.

Doing so might involve retiring outdated processes and retraining even longstanding employees, including managers. The goal is to improve efficiency and prepare for the future.

Employee resistance to change

Investing heavily in digital transformation may not always lead to the expected results for a manufacturer because the people and processes behind the technology present a challenge.

Such issues include:

- Forwarding business-sensitive data to third parties

- Opening unsafe or unknown attachments

- Incorrectly configuring machines

- Mishandling tools or equipment

3 top strategies for digital transformation in pharma

Follow these best strategies for digital transformation in pharma to ensure success.

1. Remember that digitizing isn’t the same as being fully digital

Digitizing involves converting analog materials, such as bills or brochures, into digital format. However, creating a digital business involves changing how you handle all customer interactions.

This is because customers expect seamless digital experiences across various platforms and devices. If a company fails to provide this, there is a high chance they will miss out on a potential sale.

2. Building a robust customer experience strategy is crucial

Pharmaceutical companies need to assess, enhance, and computerize every interaction, such as providers, payers, employees, and not just patients. This is crucial to gaining an edge and staying competitive in the market.

The biggest obstacle to achieving success in digital transformation and customer experience is often the organization and culture rather than technology. This means that to create exceptional customer experiences, it is essential to have internal buy-in, support from the C-suite, and clear strategies.

3. Developing and confronting target personas is essential

Personalizing experiences for different target groups is vital to optimize pharma digital transformation and improve customer journeys. Prescribers, patients, and those linked to patients all have unique expectations and demands.

Each requires customized journeys and content to establish trust and foster long-term relationships. Creating a customer journey starting with each persona is crucial in identifying all the crucial interactions tied to that specific group.

Sanofi: A use case for digital transformation in pharma

Sanofi has a factory of the future in Framingham, USA, where they invest in digital manufacturing alongside other companies. The company uses “state-of-the-art analytical techniques that forecast and avoid variations to improve performance and ensure quality.”

“Our employees work alongside “Cobots” – collaborative robots that recognize their environment to operate safely, and Autonomous Mobile Robots (AMR) will automatically transport raw materials, single-use equipment, and finished products to different points in the facility.”

The company details how its plant in Geel, Belgium, has already implemented sensors throughout the facility monitoring more than 5,000 parameters along the production processes.

Philippe Luscan, Executive Vice President of Global Industrial Affairs at Sanofi, states, “I see great scope for using digital models and simulations to transform how we plan, design and operate our facilities from the concept to delivering products to patients.”

Balance safety with technology for success in pharma

The changing landscape of the pharmaceutical industry is one of constant evolution – and digital transformation is a critical accelerant for this advancement in the healthcare industry.

In addition to keeping up with trends – such as AI and robotics – pharma professionals should remain committed to using technology wisely without compromising safety considerations as they embrace digital transformation.

To achieve success within their digital initiatives, pharma companies should prioritize safety as they move forward actively; striking the right balance between new technologies, quality control, and safe products will be essential for thriving in today’s competitive climate.

![18 Examples of AI in Finance [2025]](https://www.digital-adoption.com/wp-content/uploads/2025/06/18-Examples-of-AI-in-Finance-2025-300x146.jpg)

![14 Examples of AI in Manufacturing [2025]](https://www.digital-adoption.com/wp-content/uploads/2025/06/14-Examples-of-AI-in-Manufacturing-2025-300x146.jpg)